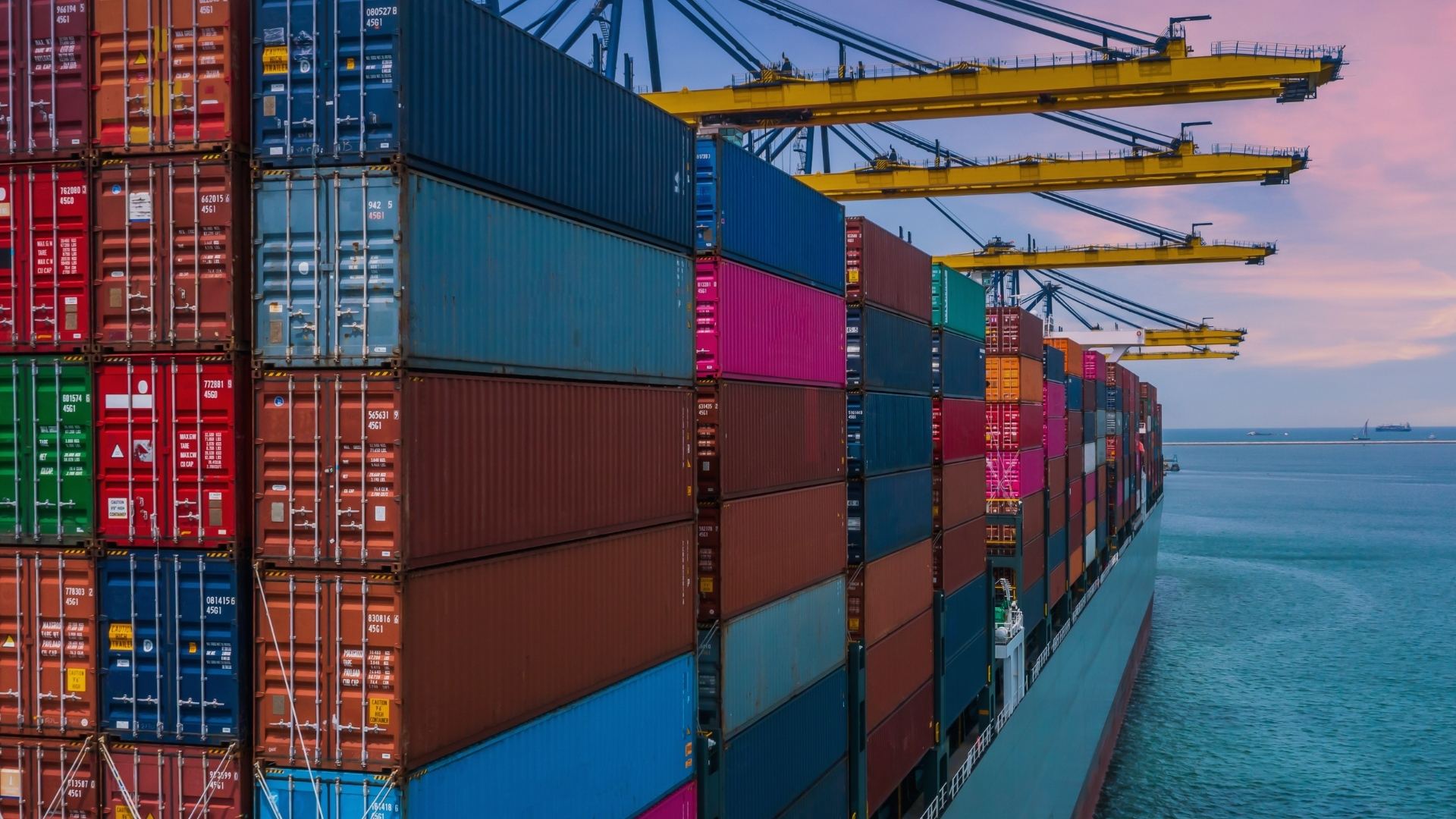

If you run shipping container transport, you already know how much of your team’s day disappears into work that isn’t planning, isn’t problem-solving, and isn’t building customer relationships.

It’s rekeying. It’s checking release status across three portals. It’s calling a subcontractor for a timestamp you should already have. It’s validating container numbers, weights, and handling instructions. It’s chasing a POD so finance can raise an invoice that should have gone out two days ago. Planners and admin teams are constantly switching context just to keep jobs moving.

What makes it tricky is that so much of this manual work is deeply embedded in day-to-day processes. It’s just “how things are done.” But over time, those small, repetitive tasks quietly drain hours from your team and money from your operation.

In shipping container transport, the real cost of the admin is not just time. It is loss of control: when release signals, port steps, proof-of-delivery and subcontractor updates live outside your operational TMS workflow, planning becomes guesswork. And in a world of tight terminal slots and expensive mistakes, guesswork is what kills margin.

This blog looks at the admin tasks and where shipping container operators lose the most control – and how connected workflows bring it back and give you back valuable time.

The hidden cost of release uncertainty in container shipping

Releasing a shipping container isn’t as simple as it sounds. Before a container can be collected, several things need to line up:

- All freight charges must be paid

- The correct documentation must be submitted

- There must be no holds from the carrier

- The terminal must confirm the container is physically available

Only once all of that is confirmed can the container actually be released. For planners, this creates an operational step that most standard transport workflows do not reflect: Plan → Prove release → Book/dispatch → Execute → Prove (POD/charges) → Invoice. That “prove release” step is where things go wrong.

The problem is that plenty of things can delay this process. Documentation issues, random inspections, port congestion, and government agency holds can all block a release — often with very little warning. When you don’t have clear visibility on what’s still outstanding, you’re planning on hope.

And the consequences are immediate. A driver arrives at a terminal with no confirmed release: the slot window is missed, the rest of the day gets replanned, and if you run past the free storage window, demurrage charges stack up fast. One unclear release status can ripple through an entire day’s schedule.

This is exactly why operators need release and handling signals inside the workflow where jobs are planned and dispatched, not in a separate portal that someone remembers to check between calls.

How Qargo helps

Container and handling status from integrations such as Portbase, Destin8, and PSA can be surfaced directly inside Qargo’s operational workflow. In the Netherlands, Qargo supports Portbase Secure Chain pickups including delegation flows, helping teams reduce rejected steps and failed collections.

In the UK, Destin8 integration provides container and customs milestone visibility so planners can see what’s cleared and what’s blocked — without logging into a separate system.

Container jobs are detail-heavy — and rekeying is where errors hide

Container transport is data-intensive by nature. A single container order can involve more than 20 data points: container number, booking reference, seal, VGM, ISO type, terminal details, depot details, cut-off times, customer references, custom references, and special handling notes. That information typically arrives scattered across PDFs, emails, and port portals.

In operations, admin teams are still rekeying those details into internal systems manually. The workload doubles, but the bigger risk is errors. A wrong digit in a container number triggers a failed pre-advice. An incorrect weight causes a gate rejection. A missed cut-off time means a shipping container doesn’t make the vessel.

To catch mistakes before they reach the terminal, teams spend hours cross-checking information and switching between systems. That’s time pulled directly away from planning, exception handling, and the work that actually keeps the operation moving.

The answer isn’t more careful data entry. It’s less data entry.

How Qargo helps

Qargo Intelligence can extract data from emails and booking confirmations, reducing manual order entry. Instead of rekeying container details line by line, planners validate AI-suggested data inside the job workflow. All customs and job-related documentation is stored alongside the job, so there’s one place to look – not five.

Subcontractors and proof creates a visibility gap

If you work with subcontractors on shipping container moves, you know how quickly visibility breaks down. Ports amplify the problem. The more terminal steps, time slots, and handovers involved, the faster operational truth fragments into WhatsApp threads, forwarded screenshots, and missed updates.

Too often, operators end up stuck in the middle – relaying updates between customers and sub-contractors, fielding questions from all sides, and trying to piece together the full picture. Without a shared operational view, planners rely on manual check-ins and driver calls, which slows decision-making when plans change mid-day.

Then there’s the proof gap. A container might be delivered, but “delivered” doesn’t mean invoice-ready in container transport. You need the POD, the correct references, and often customs confirmation before finance can raise an invoice. When that proof is stuck on a driver’s phone or buried in an email chain, invoicing stalls – and cash flow suffers.

How Qargo helps

Drivers upload PODs directly through Qargo’s mobile app, linking proof to the job immediately. Customer Portal access gives customers shared visibility on job status, reducing manual status request calls. And because proof, references, and documentation all live inside the same workflow, the path from delivery to invoice-ready is shorter and clearer.

Fewer portals, more control

On top of these three core challenges, shipping container operators are also navigating ferry bookings, equipment tracking, compliance requirements, and billing reconciliation – often across multiple disconnected systems.

The biggest time drain isn’t any single task. It’s the portal-hopping: jumping between port systems, ferry booking platforms, customs portals, and internal tools, all with different logins and different versions of the same information.

Bringing operational data into one workflow makes a measurable difference. Not because it’s a dashboard with more data on it, but because planners can see release status, execution progress, and proof capture in the same place where they plan and dispatch. Visibility in container transport isn’t a screen – it’s control inside the workflow.

With Qargo, container and terminal status signals from integrations such as Portbase, Destin8, and PSA can be surfaced directly inside the platform, reducing portal-hopping and making exceptions visible earlier.

For operators on the Irish Sea Corridor, Qargo’s ferry integrations with Irish Ferries, Stena Line, and P&O Ferries bring booking milestones into the same operational workflow used for planning and execution.

In Belgium and France, where terminal and port community system (PCS) setup vary, the principle is the same: fewer places to check, clearer job history, and faster exception handling.

Where to start streamlining your container operations

Don’t try to fix everything at once. Map your container workflow end-to-end – release readiness → port steps → dispatch → execution → proof capture → invoicing – and find where it breaks into portals, inboxes, and spreadsheets. That’s where control leaks out.

Quick wins that compound fast:

- Bring release and handling signals into the planning view so teams can act before the driver is at the gate

- Automate job creation from emails and booking confirmations to cut rekeying

- Enable digital POD capture so proof reaches finance on the same day as delivery

- Connect ferry and port milestones to the same workflow used for planning

Then measure what matters: hours saved per week, fewer missed slots, faster invoicing, fewer customer status queries.

Qargo grows with your operation – whether you’re running a small fleet into a single terminal or coordinating hundreds of container moves across multiple ports each week.

Conclusion

Admin complexity is part of shipping container logistics. Unnecessary admin doesn’t have to be.

But for container operators, visibility isn’t a dashboard. It’s control inside the workflow: knowing what’s release-ready, what’s blocked, what proof is missing, and what happens next – without stitching it together from portals, inboxes, and phone calls.

The operators who stay ahead in 2026 won’t be the ones working harder. They’ll be the ones whose workflows connect release, execution, and proof-to-invoice in one place, so decisions come from what’s true in the operation, not what’s assumed.

Ready to see how Qargo connects your container workflow, from release to invoice? Book a demo today.